-

-

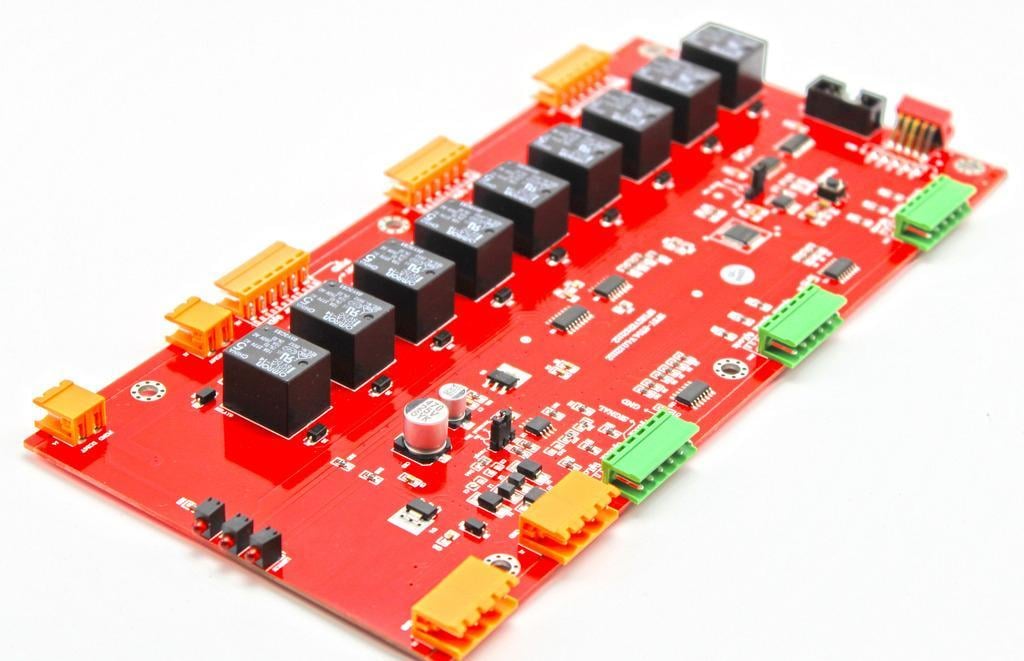

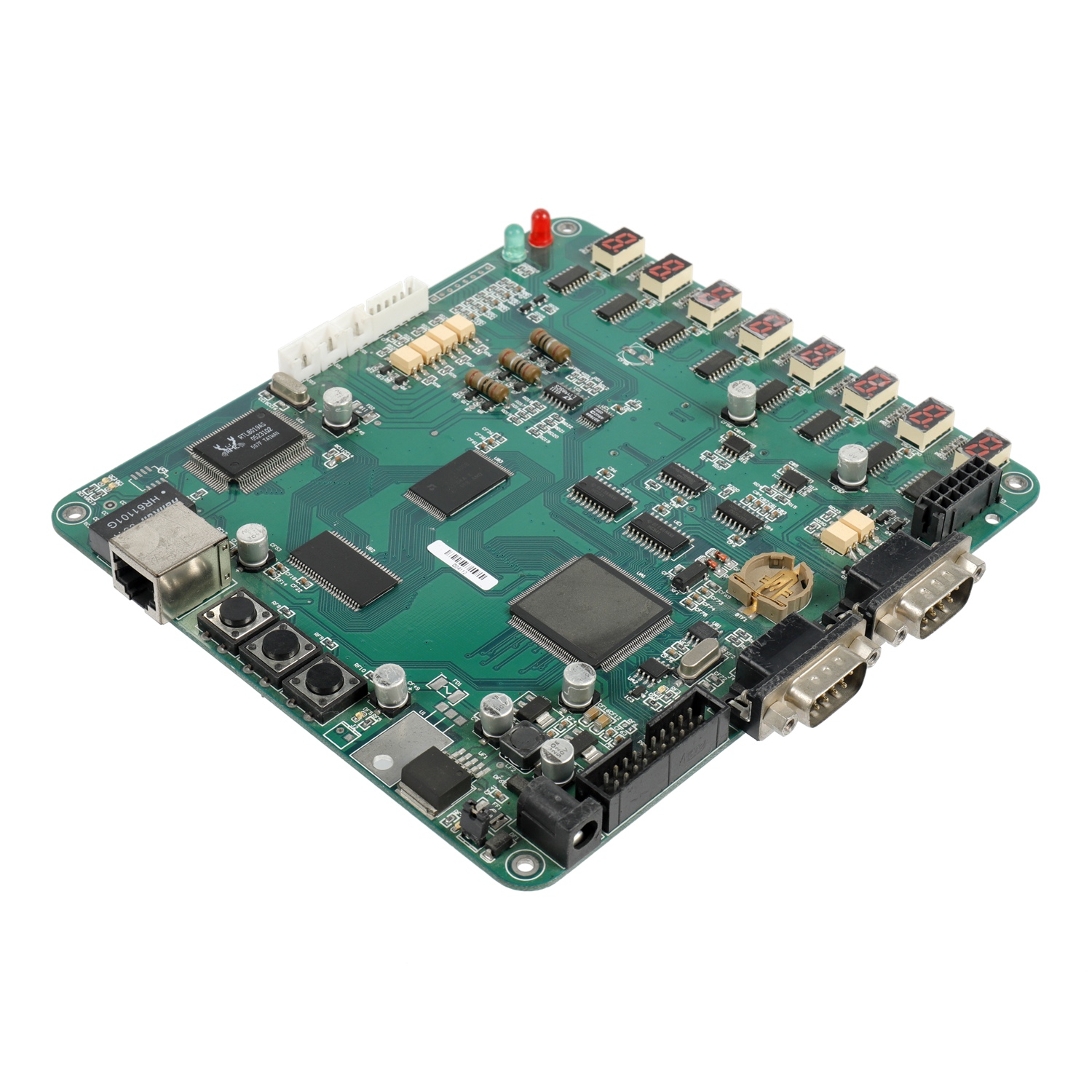

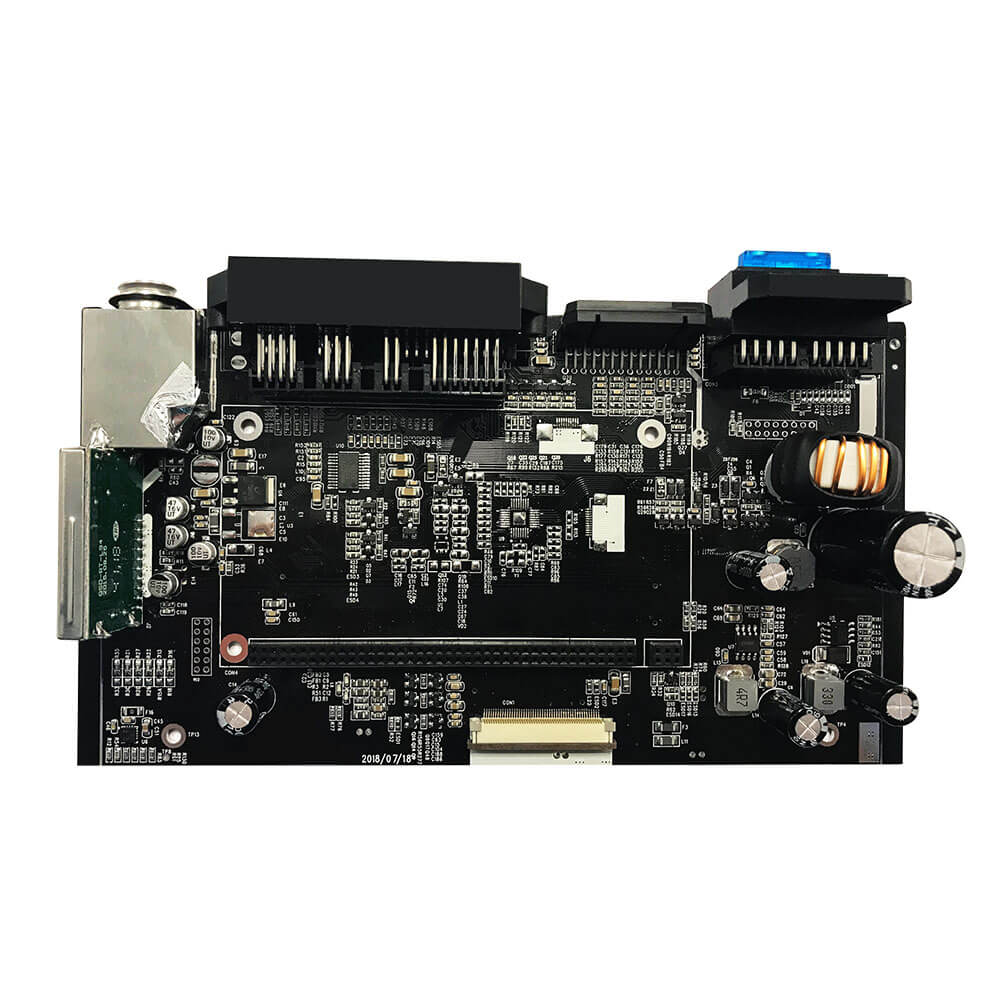

ChipsPulse is a one-stop service provider that serves the world and focuses on high-quality PCBA. The company takes speed, quality, technology and service as its core business philosophy, and independently develops MES+ERP+IOT management system to realize industrial intelligent factory. It provides customers with one-stop PCBA services in the fields of solution development, industrial control, smart home, instrumentation, Internet of Vehicles, communication power supply, medical equipment, automotive electronics, etc.

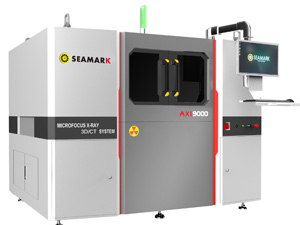

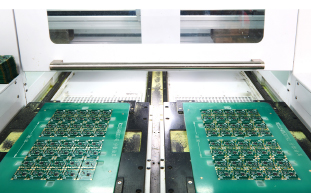

The company has nearly 150 employees and more than 50 engineering and technical quality personnel who provide professional PCBA production services to global customers 24 hours a day. The company has 8 fully automatic SMT patch production lines, 1 DIP production line, and 1 post-weld assembly production line. The factory is equipped with Japanese high-precision JUKI RS1 patch machines, Jintuo 10-zone reflow soldering, fully automatic printing machines, optical inspection AOI, KIC furnace temperature tester, X-RAY BGA inspection equipment, SPI solder paste inspection, Nitto wave soldering, Anda automatic three-conformal paint sprayer, automatic PCB cleaning machine.

Factory In ShenZhen

Over 5000m2

Factory In JianXi

30-acre Super Factory

Fast Production

Produced Within 12H

Capabilities

120K m2 Per Month

Lower Costs

best price with 1pcs

BOM

600K component parts supply

One-Stop Service

Design,board making and mounting

One-To-One Service

50 engineers for you

Contact us now for a manual quote, discounts are available for both new and old customers!

Please choose a quotation method you prefer, and our cooperation will begin!

|